Airlaid Technology: Reshaping the Quality Dimension of White Soft Napkins

The current field of paper towel manufacturing is constantly pursuing innovation. White soft airlaid paper napkins has opened up a new quality track with its subversive manufacturing process. Traditional napkin manufacturing relies on wet papermaking technology. The fibers are laid flat and interwoven under the action of water flow to form a two-dimensional plane structure. Although this technical path can meet basic usage needs, it has natural limitations in touch, toughness and functionality. The airlaid technology of white soft airlaid paper napkins reshapes the quality dimension of napkin products with a unique fiber arrangement method.

Subverting the traditional principle of airlaid technology

The production process of white soft airlaid paper napkins is an exquisite art of fiber manipulation. At the beginning of production, the selected wood pulp fibers are completely blown into a single fiber state under the action of high-speed airflow. Unlike the directional guidance of water flow on fibers in wet papermaking, high-speed airflow gives fibers the characteristics of random movement, making these single fibers disorderly and staggered during movement. Through thermal bonding or chemical bonding processes, these interwoven fibers are fixed and formed, and finally a three-dimensional and porous fiber network structure is constructed. This three-dimensional fiber distribution breaks the limitations of the traditional two-dimensional plane structure, making the internal structure of the napkin closer to the loose and porous form of the sponge.

Performance advantages of three-dimensional fiber structure

The unique three-dimensional fiber structure gives white soft airlaid paper napkins outstanding performance beyond tradition. From the perspective of tactile experience, when the hand touches the napkin, the disordered and interlaced fibers can fit the skin in all directions, like millions of soft tentacles gently wrapped. Because the fibers are not closely arranged and there are a lot of pore spaces, the napkin has a light and fluffy texture as a whole, and the natural rebound of the fibers can be felt every time you press it. In terms of physical properties, the fiber network of the three-dimensional structure has excellent mechanical support capabilities. When the napkin is squeezed or rubbed by external force, the interlaced fibers can support each other and evenly distribute the pressure throughout the structure. This characteristic effectively prevents a single fiber from breaking or flattening due to concentrated force, allowing the napkin to remain fluffy and soft after repeated use, completely solving the problem that traditional napkins become hard when exposed to water and are easily deformed after repeated use.

Quality verification in multiple scenarios

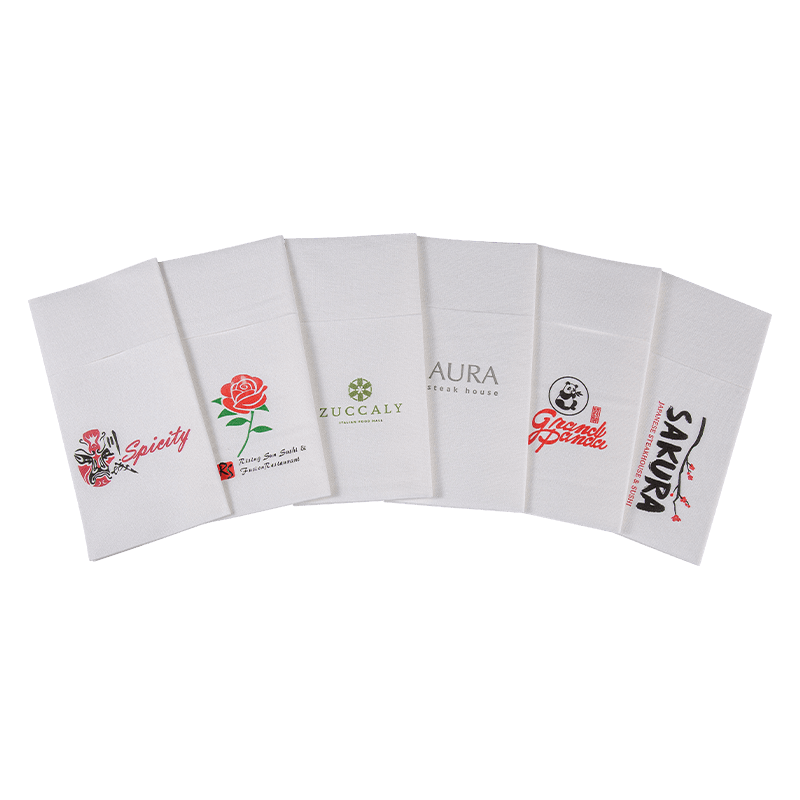

With its unique manufacturing process and performance advantages, white soft airlaid paper napkins show extraordinary value in a variety of scenarios. In daily dining scenarios, it can gently wipe the corners of the mouth to avoid irritation to the lip skin due to rough materials; when used for post-meal cleaning, its excellent water absorption and fiber toughness can not only efficiently absorb water stains and oil stains, but also will not be easily damaged or produce paper scraps. In the field of maternal and child care, its extremely soft touch has become an ideal choice for caring for the delicate skin of babies, and it will not cause redness or allergic reactions even if it is wiped frequently. In high-end catering, hotel services and other scenarios, the fluffy texture and exquisite touch of this napkin enhance the quality style of the overall service and meet consumers' pursuit of quality life.

White soft airlaid paper napkins are based on a three-dimensional fiber structure constructed by air-laid technology, which fundamentally breaks through the performance bottleneck of traditional napkins. It redefines the quality standard of napkin products, and through technological innovation, it brings consumers an unprecedented user experience, becoming a model of technological innovation and quality upgrade in the field of paper towel manufacturing.

English

English  Español

Español