How Are Airlaid Napkins Manufactured and What Makes Them Unique?

In the fast-evolving world of disposable tableware, airlaid napkins have carved a distinct niche. They are increasingly preferred in hospitality, catering, and home settings due to their superior texture, absorbency, and presentation appeal. Unlike traditional paper napkins, airlaid napkins offer a combination of strength, softness, and design flexibility that meets modern consumer expectations.

Understanding Airlaid Napkins

Airlaid napkins are produced using a unique airlaid technology. This process involves distributing short wood fibers into an air stream to form a uniform web, which is then bonded using chemical or thermal binders. This differs from conventional paper production, where fibers are suspended in water and drained to form sheets. The result is a thicker, softer, and highly absorbent napkin capable of withstanding liquids and maintaining shape.

Airlaid napkins are widely used in catering, fine dining, and cocktail settings. Variants such as cocktail airlaid paper napkins are smaller in size, typically designed for beverages, hors d’oeuvres, and casual gatherings, but they carry the same premium qualities as larger napkins.

The Airlaid Manufacturing Process

The manufacturing process of airlaid napkins is technically sophisticated and requires specialized equipment. Below is a breakdown of the typical stages:

Fiber Preparation

Raw materials, typically pulp or cellulose fibers, are first cleaned and fluffed. This ensures uniform fiber length and removes impurities that could compromise napkin quality. For cocktail airlaid paper napkins, finer fibers may be used to achieve a softer touch suitable for delicate usage.

Airlaid Web Formation

Prepared fibers are introduced into an air stream. The fibers are distributed evenly over a moving belt, forming a loose web. Unlike traditional paper sheets, no water is used in this stage, making the web lightweight but voluminous.

Binding and Bonding

The web is then bonded to maintain structural integrity. Common methods include:

- Thermal bonding: Applying heat to thermoplastic binders within the fibers.

- Chemical bonding: Spraying the web with a binder solution that dries to hold fibers together.

Calendering

Calendering smooths and compresses the web to achieve uniform thickness and a soft surface. This step is crucial for napkins that will undergo hot stamping, as a smooth surface ensures clean prints.

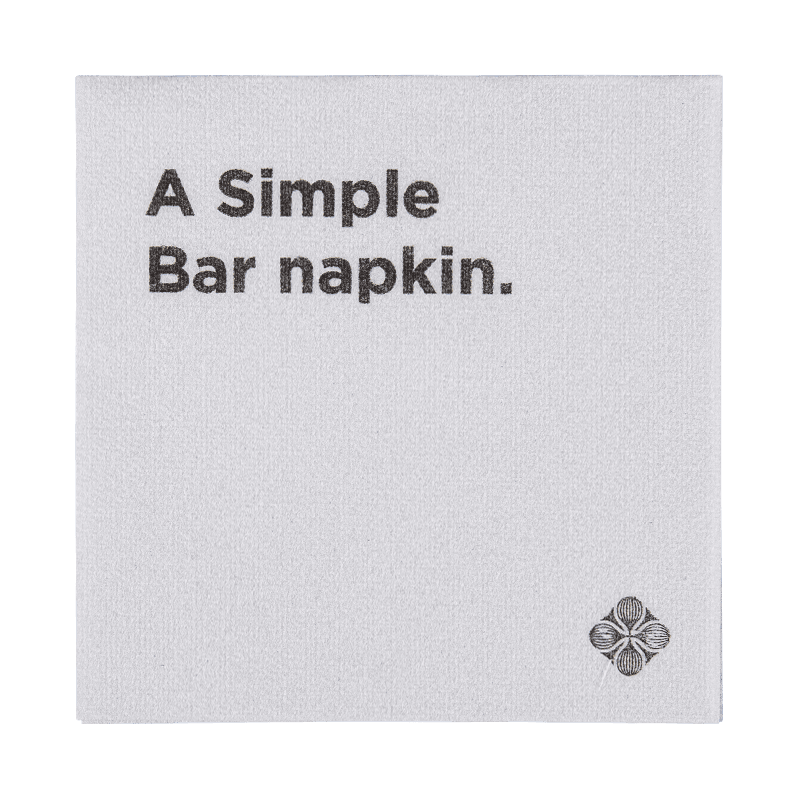

Printing and Hot Stamping

Airlaid napkins are highly compatible with printing techniques, including hot stamping. Hot stamping involves transferring a metallic or colored foil onto the napkin using heat and pressure. This allows intricate designs, logos, or patterns to be applied, enhancing visual appeal for special events or premium presentations.

Cutting, Folding, and Packaging

After bonding and finishing, the large airlaid sheets are cut into the desired napkin size. Folding machines create various styles, including cocktail folds, multi-fold designs, or rolled formats. Napkins are then packaged for distribution.

Comparison with Regular Paper Napkins

Airlaid napkins differ significantly from traditional paper napkins in terms of structure, performance, and aesthetics. The following table highlights key distinctions:

| Feature | Airlaid Napkins | Regular Paper Napkins |

|---|---|---|

| Texture | Soft, cloth-like | Thin, rough |

| Absorbency | High, holds liquids without disintegration | Moderate, can tear when wet |

| Strength | Strong, resists tearing even when wet | Weaker, prone to tearing |

| Thickness | Voluminous, fluffy | Flat, less cushion |

| Design Options | Hot stamping, embossing, printing | Limited printing, minimal embossing |

| Cost | Higher production cost | Lower production cost |

| Use Cases | Catering, cocktail parties, premium dining | Everyday casual use |

Advantages of Airlaid Napkins

The rising popularity of airlaid napkins is linked to several advantages over conventional napkins:

Enhanced Absorbency: Airlaid napkins can absorb multiple times their weight in liquid without losing shape, making them ideal for messy or beverage-centric occasions.

Premium Feel: The soft, cloth-like texture elevates the dining experience, contributing to perceived quality and sophistication.

Durability: They maintain structural integrity even when wet, reducing the likelihood of tears or disintegration during use.

Customizable Designs: Techniques such as hot stamping allow intricate designs, logos, and branding elements to be applied directly to napkins, making them suitable for upscale events or corporate functions.

Environmental Considerations: Many airlaid napkins are made from renewable pulp fibers and can be fully biodegradable, aligning with sustainable product trends.

Specialized Variants: Cocktail Airlaid Paper Napkins

Cocktail airlaid paper napkins are a specialized subset. These napkins are smaller in size but share the same high-quality airlaid construction. Their compact dimensions make them suitable for serving beverages, finger foods, and hors d’oeuvres at events. The manufacturing process mirrors standard airlaid napkins but with additional precision in folding and cutting to suit beverage service.

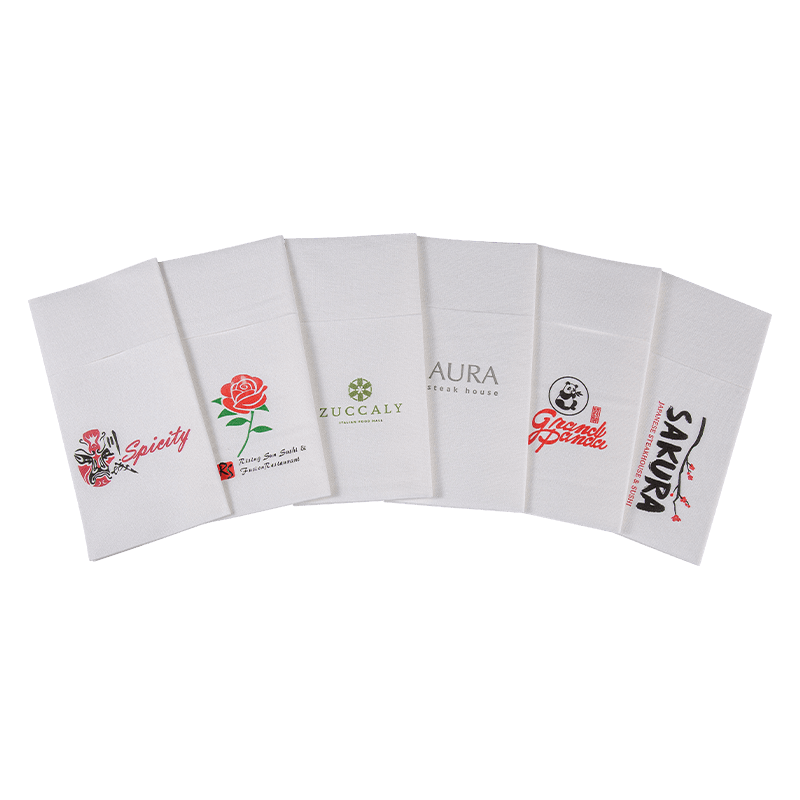

Cocktail airlaid paper napkins are often sold in packs with decorative prints or hot-stamped designs, enhancing table presentation. Their softness, absorbency, and design versatility make them a preferred choice for bars, hotels, and upscale catering services.

Quality Control in Airlaid Napkin Production

Quality control is essential in the airlaid napkin industry to maintain consistent performance. Critical checkpoints include:

- Fiber quality: Ensuring uniformity, strength, and cleanliness.

- Web uniformity: Monitoring thickness, density, and even distribution.

- Bonding strength: Testing resistance to tearing and absorbency under stress.

- Finishing precision: Checking print, embossing, and hot stamping accuracy.

- Packaging integrity: Ensuring folds, packs, and presentation meet client requirements.

Automated monitoring systems are commonly used to detect irregularities during production, ensuring each napkin meets high standards of performance and aesthetics.

Applications Beyond Dining

While airlaid napkins are predominantly associated with dining and catering, they also find applications in other sectors:

- Event planning: Wedding receptions, cocktail parties, and conferences.

- Hospitality: Hotels, resorts, and airlines often use airlaid napkins for a premium guest experience.

- Corporate branding: Custom-printed airlaid napkins with hot stamping can reinforce brand identity.

- Home use: Premium households favor them for their comfort, absorbency, and upscale appearance.

Trends Driving Airlaid Napkin Adoption

Several trends contribute to the growing adoption of airlaid napkins:

Premiumization of Disposable Products: Consumers increasingly prefer disposable items that mimic the feel of reusable cloth.

Sustainability: Airlaid napkins made from biodegradable pulp appeal to environmentally conscious buyers.

Customization: Hot stamping and embossing allow for bespoke designs for events and branding.

Convenience: Single-use napkins reduce cleaning efforts without compromising quality or presentation.

Key Considerations for Buyers

When selecting airlaid napkins, consider the following:

- Fiber Type: Soft pulp fibers improve texture and absorbency.

- Thickness: Thicker napkins provide a more luxurious feel and superior absorbency.

- Printing Capability: Ensure compatibility with hot stamping or custom printing.

- Size and Fold Type: Choose sizes appropriate for intended use, such as standard dining or cocktail napkins.

- Environmental Impact: Verify biodegradability and certifications for eco-friendly products.

Airlaid Napkins vs Other Premium Alternatives

Airlaid napkins are often compared with other high-quality disposable napkins like tissue-based or embossed paper napkins. The table below summarizes these comparisons:

| Feature | Airlaid Napkins | Tissue Napkins | Embossed Paper Napkins |

|---|---|---|---|

| Texture | Soft, cloth-like | Soft, thin | Rougher, limited softness |

| Absorbency | High | Moderate | Moderate |

| Strength (wet) | High | Low | Low |

| Design Options | Hot stamping, embossing | Limited printing | Embossing only |

| Cost | Higher | Lower | Medium |

| Presentation Appeal | Premium | Basic | Moderate |

This comparison reinforces why airlaid napkins, particularly cocktail airlaid paper napkins, are the preferred choice for premium dining experiences.

Conclusion

Airlaid napkins represent a blend of innovation, functionality, and design flexibility. Their unique airlaid production process, combined with bonding, calendering, and finishing techniques such as hot stamping, ensures a product that is soft, absorbent, strong, and visually appealing. By understanding the production process and unique advantages of airlaid napkins, buyers and suppliers can better appreciate their value in both practical and aesthetic terms.

FAQ

1. What are airlaid napkins made of?

Airlaid napkins are primarily made from pulp or cellulose fibers, distributed into an air stream and bonded with thermal or chemical binders to form a soft, strong, and absorbent sheet.

2. How do cocktail airlaid paper napkins differ from regular airlaid napkins?

Cocktail airlaid paper napkins are smaller and designed specifically for serving beverages and appetizers. They maintain the same soft texture, absorbency, and design flexibility.

3. What is hot stamping, and why is it used on airlaid napkins?

Hot stamping is a printing process that transfers foil onto the napkin using heat and pressure. It allows intricate designs, logos, and metallic accents, enhancing the visual appeal.

4. Are airlaid napkins environmentally friendly?

Yes, most airlaid napkins are made from renewable pulp fibers and are biodegradable, aligning with sustainable practices.

5. Why choose airlaid napkins over regular paper napkins?

Airlaid napkins offer superior softness, absorbency, strength, and design versatility, making them ideal for premium dining, catering, and special events.

English

English  Español

Español