When Art and Practicality Dance Together: The Technological Innovation of Full-Printing 2-Ply Paper Napkins Paper

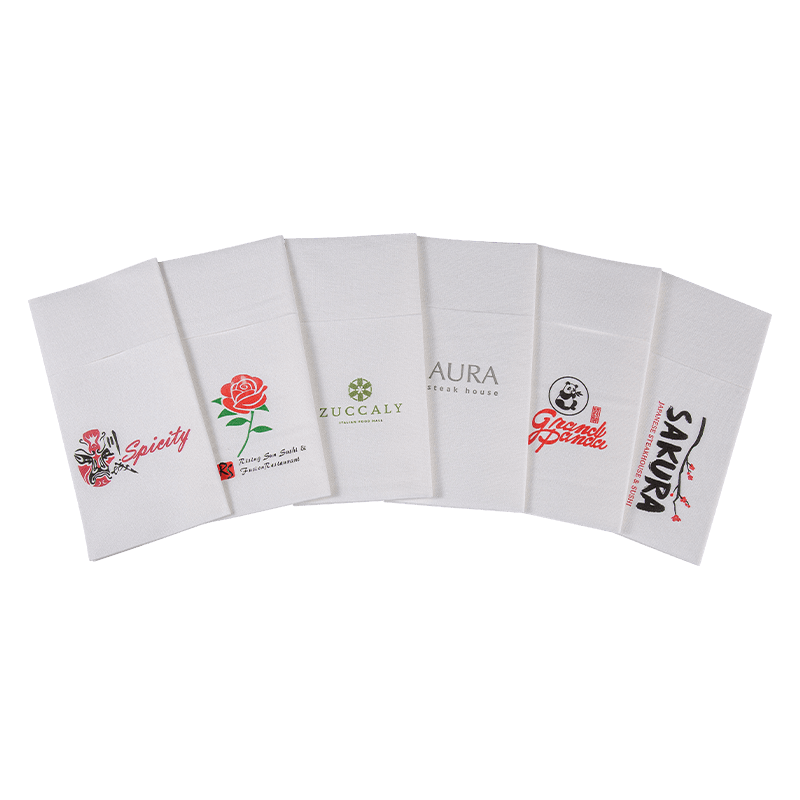

In the innovative development of catering paper, full-printing 2-ply paper napkins paper, with its unique double-layer structure design, not only achieves the combination of beauty and practicality, but also achieves a qualitative leap in touch and durability. This structure is not a simple superposition, but through precise process control and scientific material combination, it brings users an unprecedented user experience.

The cornerstone of structural stability

The double-layer structure of full-printing 2-ply paper napkins paper, its stability comes from the precise pressing process. During the production process, the three major parameters of temperature, pressure and time need to be precisely controlled. The appropriate temperature can soften the fibers on the surface of the paper, so that they can be better interwoven under pressure; and the appropriate pressure ensures that the two layers of paper fit closely and form a strong interlayer bonding force; the control of time parameters is also critical. If it is too short, it cannot be fully pressed, and if it is too long, it may damage the fiber structure of the paper. By optimizing these three parameters in a coordinated manner, the risk of paper delamination is avoided, giving the napkin a unique three-dimensional fluffy feeling.

The secret of touch innovation

The three-dimensional fluffy feeling created by the double-layer structure is the core of its touch innovation. Different from the thinness and roughness of traditional single-layer napkins, the two layers of full-printing 2-ply paper napkins paper form a special spatial structure after lamination. When the fingers touch the paper, this fluffy structure can provide moderate cushioning, like a gentle rebound, bringing a silky soft touch. From a microscopic perspective, the paper fibers form a unique arrangement and interweaving method during the lamination process, making the surface no longer flat and monotonous, but showing subtle ups and downs. These changes in microstructure reduce the friction between the skin and the paper, making the wiping action smoother and more comfortable. Whether it is wiping the corners of the mouth during daily meals or touching the tableware when cleaning, you can clearly feel its delicate and soft texture, completely saying goodbye to the rough experience brought by traditional napkins.

The key to improved durability

In addition to the optimization of touch, the double-layer structure also performs well in durability. The core lies in the realization of the stress dispersion mechanism. When the napkin is subjected to external force, the single-layer napkin is often easily damaged due to excessive local force. The double-layer structure of full-printing 2-ply paper napkins paper can evenly disperse the external force on the two layers of paper. The upper and lower layers of paper share the external force through close bonding, avoiding local stress concentration. This stress dispersion effect effectively improves the tensile strength and folding resistance of the napkin. In actual use, whether it is facing the wiping of oily tableware or the need to wrap sharp objects, full-printing 2-ply paper napkins paper can maintain the integrity of the structure and is not easy to tear or break. Compared with traditional single-layer napkins, the service life is significantly extended, meeting the diverse needs of users.

Synergy of materials and processes

The improvement of full-printing 2-ply paper napkins paper in touch and durability is inseparable from the synergy of materials and processes. In terms of material selection, paper with fine fibers and high softness is selected to meet the requirements of touch; and fiber raw materials with high toughness and strength are selected to meet the requirements of durability. In terms of technology, in addition to the precise lamination process, special surface treatment and fiber optimization technology are also used. The synergy of these materials and processes makes full-printing 2-ply paper napkins paper achieve a perfect balance between touch and durability, becoming an innovative benchmark in the field of catering paper.

English

English  Español

Español