Production equipment and key technologies for Paper Napkins with Hot Stamping

Fiber distribution technology

The production ofPaper Napkins with Hot Stamping begins with the uniform distribution of fibers. This is one of the core technologies for the production of air cushion napkins. The fibers are evenly distributed on the mesh belt through high-speed airflow to form a fluffy fiber layer. This step is crucial to the softness and water absorption of the napkins. The uniformity of fiber distribution directly affects the touch and performance of the final product. Our company uses advanced airflow forming technology in this link to ensure the high-quality forming of the fiber layer.

The core of fiber distribution technology lies in how to lay the fibers evenly on the mesh belt. This process requires precise control of the speed and direction of the airflow to ensure that the thickness and density of the fiber layer are uniform. Shuangjie Paper uses an advanced airflow control system in this link, which can flexibly adjust the airflow parameters according to different fiber types and production requirements to ensure the high-quality forming of the fiber layer. In addition, the company has also introduced an automated monitoring system to monitor the state of fiber distribution in real time, promptly detect and correct problems in production, and ensure the stable quality of each batch of products.

Chemical treatment technology

During the production process, the fibers may need to be chemically treated to enhance their water absorption and durability. These treatments usually include the addition of wet strength agents, softeners, etc. Wet strength agents can improve the strength of napkins in wet environments, while softeners can improve their touch comfort. The application of chemical treatment technology makes hot-stamped paper napkins not only beautiful in appearance, but also meet the functional needs in actual use.

According to market demand, the company flexibly adjusts the chemical treatment formula to ensure that the product achieves the best balance in terms of water absorption and durability. For example, by adding wet strength agents, Shuangjie Paper's hot-stamped paper napkins can still maintain high strength in wet environments, while the use of softeners makes the napkins more comfortable to the touch and improves the user experience. The application of chemical treatment technology is not limited to wet strength agents and softeners. Shuangjie Paper has also introduced chemical additives such as antibacterial agents and mildew inhibitors to further improve the hygienic properties of the product. The application of these chemical treatment technologies makes hot-stamped paper napkins not only attractive in appearance, but also performs well in actual use, which can meet the needs of high-end users.

Forming and cutting technology The treated fiber layer undergoes processes such as forming and cutting, and finally becomes an air cushion napkin with a specific shape and size. This process requires high-precision equipment and technical support to ensure that the size and shape of each napkin meet the standards. Shuangjie Paper uses equipment such as fully automatic embossing printing and folding machines in this process, which can efficiently complete the forming and cutting of napkins while ensuring the consistency and aesthetics of the product.

Shuangjie Paper's fully automatic embossing printing and folding machine is a highlight of its production equipment. This equipment not only achieves high-precision embossing and printing effects, but also greatly improves production efficiency. With this equipment, Shuangjie Paper can quickly complete the forming and cutting of napkins, ensuring that the size and shape of each napkin meet customer requirements.

The core of forming and cutting technology lies in how to ensure that the size and shape of each napkin meet the standards. Shuangjie Paper uses high-precision cutting equipment in this process, which can accurately cut napkins of various shapes and sizes according to different design requirements.

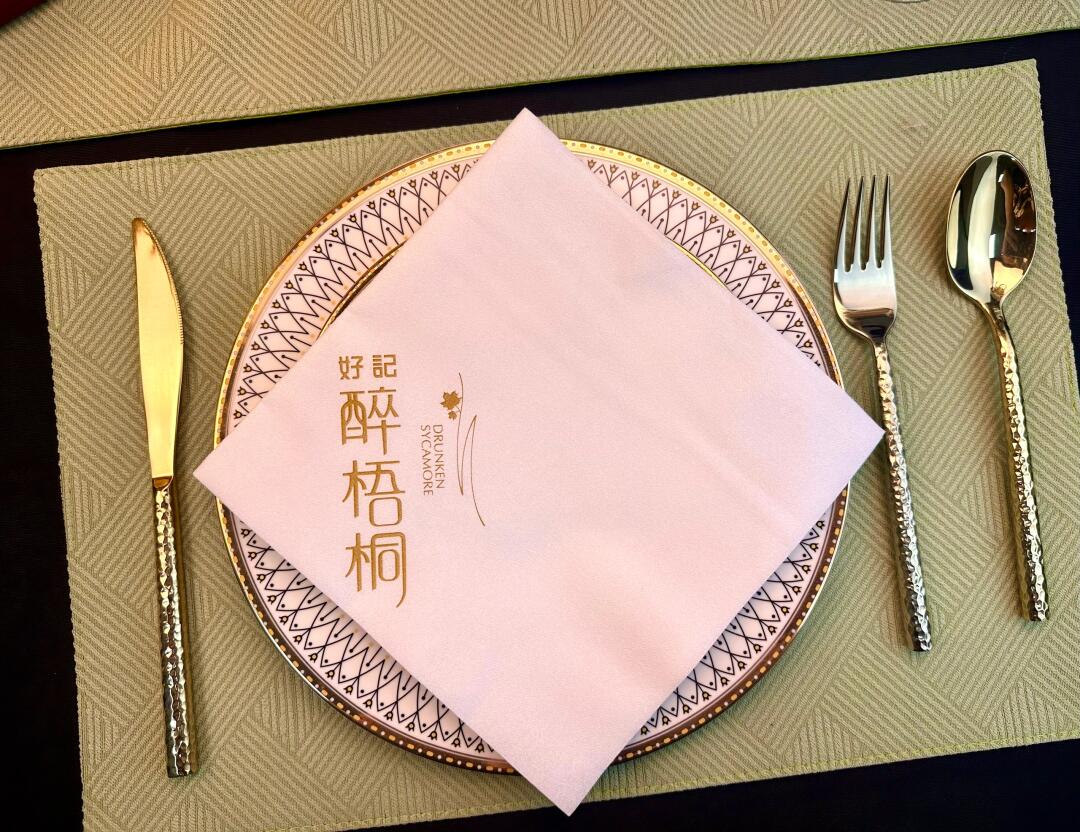

Hot stamping technology Hot stamping technology is one of the core processes of hot stamping paper napkins. By applying metal foil or color to paper using heat and pressure, the hot stamping process can form shiny and eye-catching designs on napkins. This technology not only enables the embedding of complex logos, patterns or text, but also enhances the product's sense of class, making it an ideal choice for high-end events and occasions. Hot stamping paper napkins are known for their elegant and sophisticated appearance, thanks to the application of this technology.

High-end dust-free napkins can be customized according to customer needs, and multi-color napkins and dust-free napkins can also be customized. A variety of specifications and sizes are available, and can be customized according to drawings. This flexible production capacity enables

Shuangjie Paper to meet diverse market needs. Through hot stamping technology, Shuangjie Paper is able to provide customers with napkins with complex logos or patterns, making it an ideal choice for high-end events and occasions.

The core of hot stamping technology lies in how to accurately apply metal foil or color to paper. This link uses high-precision hot stamping equipment, which can accurately control heat and pressure according to different design requirements to ensure the uniformity and consistency of the hot stamping effect. The company has introduced an automated detection system to monitor errors in the hot stamping process in real time to ensure the stable quality of each napkin.

English

English  Español

Español